(727) 726-5336 • sales@mastercuttool.com

Tool Coatings

Mastercut Tool supports our proven cutting -tool geometries with a complete range of time-tested PVD coatings, including the very latest in multi-layer, nanocomposite options such as nACo and nACRo. Our commitment to leading edge technology equates to tooling with consistent, repeatable performance where it counts, at the spindle.

PowerT (Titanium Nitride, TiN)

Color: Gold

Vickers Hardness: approximately 2,300 Vickers

General purpose, entry level over uncoated carbide

PowerC (Titanium Carbon Nitride, TiCN)

Color: Ranges from slight violet to brown-gray

Vickers Hardness: approximately 3,000 Vickers

Used on ferrous, non-ferrous and non-magnetic stainless steel

Good abrasion resistance, low heat resistance, for applications requiring low RPMs and high thrust

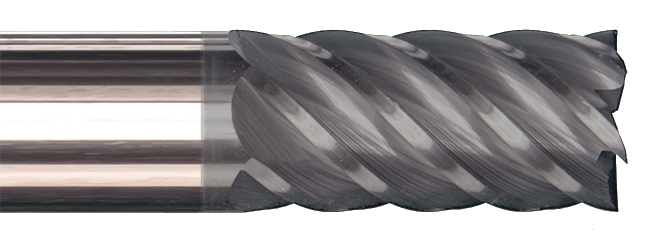

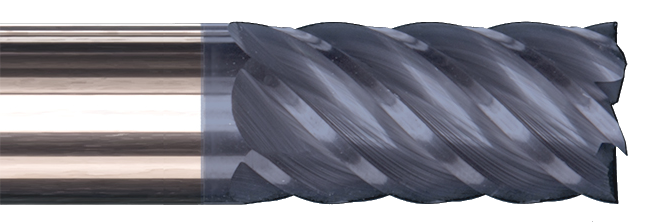

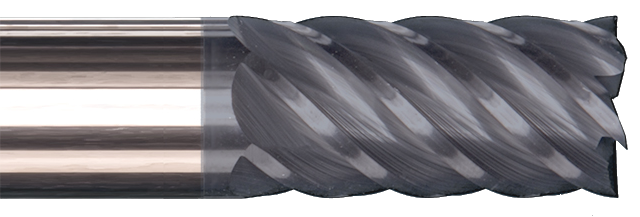

PowerA (Aluminum Titanium Nitride, AlTiN)

Color: Dark Gray

Vickers Hardness: approximately 3,600 Vickers

Nickel Alloys, Stainless Steel, Hardened Steels, Tool Steels, Cast Iron

An excellent broad spectrum grade. May be run in dry or minimum quantity lubrication applications, where heat can be a problem. Also handles light chip loads very well

PowerZ (Zirconium Nitride, ZrN)

Color: Dull Gold

Vickers Hardness: approximately 2,800 Vickers

Outstanding on aluminum, including high silica aluminum. Can also be used on cast iron, stainless steels, titanium

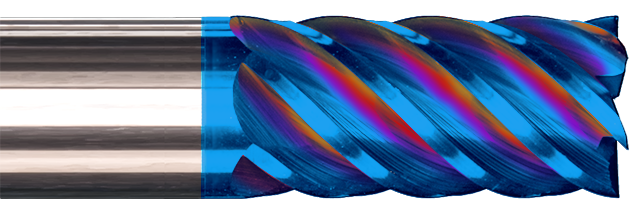

PowerN (nACo) nano-composite (nc-AlTiN)/(a-Si3Na4)

Color: Varying hues of red and blue.

Vickers Hardness: approximately 4,500 Vickers

Outstanding performance in superalloys, hard material machining, and high heat applications.

PowerNR (nACRo) nano-composite (nc-AlCrN/a-Si3Na4)

Color: Gray

Vickers Hardness: 4,000 Vickers

Outstanding in high heat applications, better resistance to shock and chipping than nACo, for tough, aggressive cutting applications.

PowerDLC (Diamond Like Carbon)

Color: Variable gray to black

Vickers Hardness: approximately 4,000 Vickers

Non-ferrous metals, high silicone aluminum, copper, plastic, graphite, fiberglass or reinforced plastics

Can be applied to any carbide substrate

PowerRD (Real Diamond)

Color: Variable gray to black

Vickers Hardness: approximately 8,000 Vickers

Non-ferrous, metals, aluminum, graphite, green ceramics

Requires 6% cobalt carbide for application

Mastercut Tool Corp. (c) 2021